We use cookies to personalise site content, social media features and to analyse our traffic. We also share information about your use of this site with our advertising and social media partners.

2 minutes, 49 seconds

-4 Views 0 Comments 0 Likes 0 Reviews

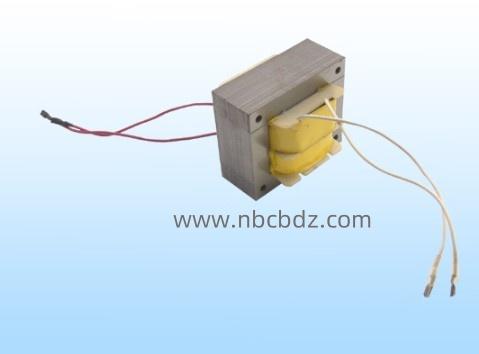

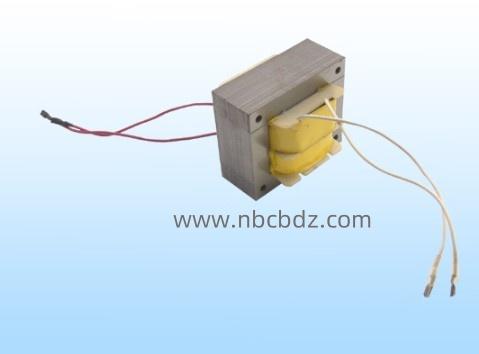

Low-frequency Transformer Factory plays an essential role in determining the efficiency, reliability, and performance of industrial machinery. In a Low-frequency Transformer Factory, meticulous design decisions—from core material selection to winding configurations—directly influence the operational stability of devices and overall energy consumption. A well-engineered low-frequency transformer ensures consistent voltage regulation, minimizes losses, and supports smooth operation of heavy-duty industrial equipment.

One of the main factors affecting industrial applications is the choice of magnetic core materials. Low-frequency operations require materials that balance magnetic permeability and low core loss. This ensures that transformers can deliver steady energy to connected machines without overheating or causing voltage fluctuations. Proper insulation and structural support further contribute to long-term operational safety and performance.

Manufacturing techniques in the factory also impact transformer reliability. Automation, precision tooling, and standardized assembly methods allow consistent output across production batches. Nbcbdz incorporates these approaches to maintain high levels of quality control, ensuring that industrial equipment operates predictably and energy is efficiently utilized throughout the system.

Thermal management is another critical aspect. Transformers designed for low-frequency applications often handle significant currents, generating heat that must be managed carefully. Correct spacing, ventilation, and heat-resistant materials allow transformers to dissipate heat effectively, protecting both the transformer and the connected industrial machinery from damage and efficiency loss.

Additionally, testing protocols in Nbcbdz factories include rigorous verification of voltage stability, insulation integrity, and mechanical durability. These measures confirm that each transformer can handle real-world industrial loads and maintain operational performance under varying conditions. By optimizing these design and production factors, industrial manufacturers benefit from reduced maintenance needs and improved energy efficiency.

Attention to detail in winding density, coil alignment, and core assembly can further enhance low-frequency transformer efficiency. Manufacturers who understand these subtleties can produce equipment with lower energy losses, stable output, and prolonged lifespan.

Through these combined strategies, Nbcbdz demonstrates how a modern Low-frequency Transformer Factory can enhance industrial operations, offering reliable and efficient solutions tailored to heavy machinery. Learn more about our offerings at https://www.nbcbdz.com/product/

Copyright © 2025

Share this page with your family and friends.